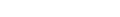

Pharmaceutical Centrifugal Sifter Machine

Product Details:

- Material Stainless Steel

- Computerized No

- Control Mode Manual

- Weight (kg) 500-1000 Kilograms (kg)

- Warranty Yes

- Click to View more

Pharmaceutical Centrifugal Sifter Machine Price And Quantity

- 1 Unit

Pharmaceutical Centrifugal Sifter Machine Product Specifications

- Manual

- Stainless Steel

- No

- 500-1000 Kilograms (kg)

- Yes

Pharmaceutical Centrifugal Sifter Machine Trade Information

- 50 Unit Per Month

- 10 Days

- All India

Product Description

The Pharmaceutical Centrifugal Sifter Machine is a manual control mode machine made of stainless steel, weighing between 500-1000 kilograms. It is designed for pharmaceutical applications, ensuring efficient and reliable sifting of powders and granules. The machine is durable and comes with a warranty, providing peace of mind to the users. Its robust construction and high-quality material make it suitable for use in pharmaceutical manufacturing facilities, ensuring compliance with industry standards.

Application & Process : The Centrifugal Sifter, manufactured by AURUS, is a highly efficient and versatile machine used for the separation and sieving of fine powders and granular materials. It employs centrifugal force to achieve high-speed particle separation, ensuring accurate grading and removal of oversized or undersized particles.

Function and Operation: The Centrifugal Sifter operates by introducing the material into a cylindrical screen chamber. As the machine rotates at high speed, centrifugal force pushes the particles against the screen, causing the fine particles to pass through the screen mesh while the larger particles are propelled towards the outer edges of the chamber and discharged through an outlet. This mechanism allows for rapid and efficient sieving, resulting in precise particle separation.

Advantages of Centrifugal Sifter: The Centrifugal Sifter offers several advantages over traditional sieving methods:

- High Efficiency: The centrifugal action of the machine ensures quick and efficient separation of particles, leading to increased productivity and reduced processing time.

- Accurate Sieving: The Centrifugal Sifter provides precise particle size classification and eliminates oversized or undersized particles, ensuring consistent product quality.

- Versatility: It can handle a wide range of materials, including powders and granules, making it suitable for various industries such as pharmaceuticals, chemicals, food processing, and more.

- Easy Maintenance: The design of the Centrifugal Sifter allows for easy cleaning and maintenance, reducing downtime and optimizing operational efficiency.

- Customization: AURUS offers customization options to meet specific requirements, including screen mesh sizes, material construction, and additional features such as dust-tight enclosures or automated discharge systems.

Features :

- Flawless screening and removal of foreign contaminants and other adulteration

- Break soft lumps into powders (deagglomeration) and remove oversized products (scalping) efficiently

- Minimise downtime through hygienic removal of dust and other fine residue from granular feed

- Effortless ownership experience due to minimal noise, heat and dust

- Ultimate value on investment with multiple variant options based on requirement

|

Name |

UCS-LAB |

UCS-20 |

UCS-50 |

|---|---|---|---|

|

Motor |

0.75HP |

2HP |

5HP |

|

Capacity |

1000kg/hr |

2000kg/hr |

5000kg/hr |

FAQs of Pharmaceutical Centrifugal Sifter Machine:

Q: What is the weight range of the Pharmaceutical Centrifugal Sifter Machine?

A: The weight of the machine ranges from 500-1000 kilograms.Q: Is the control mode computerized or manual?

A: The control mode of the machine is manual.Q: What is the material of construction for the machine?

A: The machine is made of stainless steel.Q: Does the machine come with a warranty?

A: Yes, the machine comes with a warranty.Q: What is the primary application of the Pharmaceutical Centrifugal Sifter Machine?

A: The machine is designed for efficient and reliable sifting of powders and granules in pharmaceutical manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS